On a large coal terminal upgrade project in British Columbia, electrical contractor Houle Electric faced monumental challenges in managing thousands of tasks, drawings, and test reports. The two-year project required ongoing administrative maintenance to manage numerous drawings updates and adjustments to the project scope. Strict documentation and reporting requirements added to the project complexity. Houle Electric recognized an immediate need to streamline processes with customizable field management software.  Houle turned to Fieldwire to simplify the project’s complexities. The tool provided key transparency to the client, and helped increase efficiency throughout the project’s stages.

Houle turned to Fieldwire to simplify the project’s complexities. The tool provided key transparency to the client, and helped increase efficiency throughout the project’s stages.

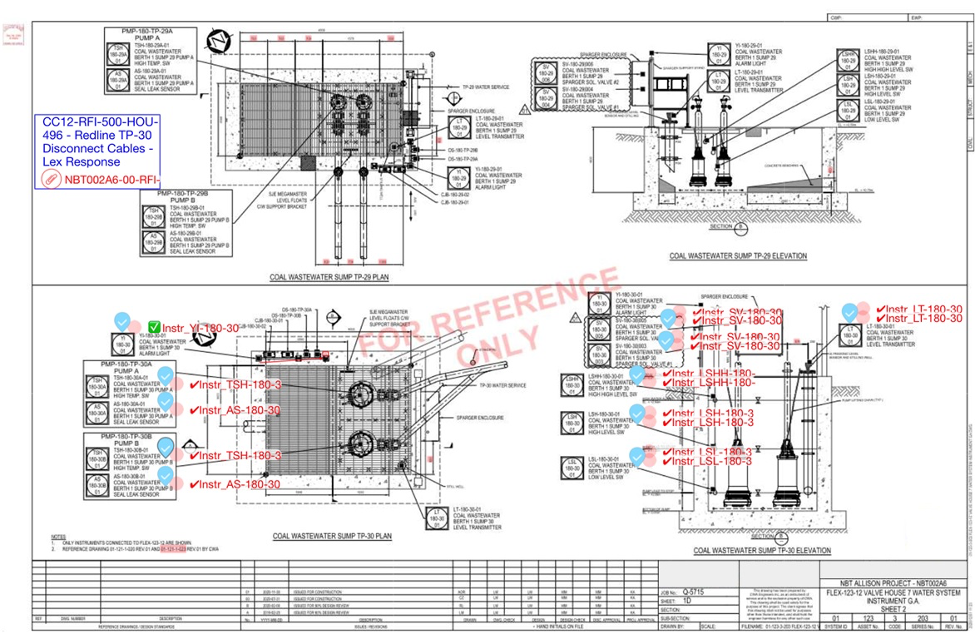

The Neptune Terminals project in North Vancouver, valued at nearly $1 billion, calls for expanding the terminal capacity from 12.5 million metric tonnes (MT) to 18.5 million MT per year. New equipment includes a coal train dumper building that tips the coal in incoming rail cars onto a series of conveyors. The conveyors supply stacker-reclaimers on the terminal, placing coal in a stockpile area, from where it can be loaded to vessels for export. Owner Neptune Bulk Terminals Ltd. and its mining partner Teck Resources Ltd. anticipate completing the project in late 2021.

Key Transparency

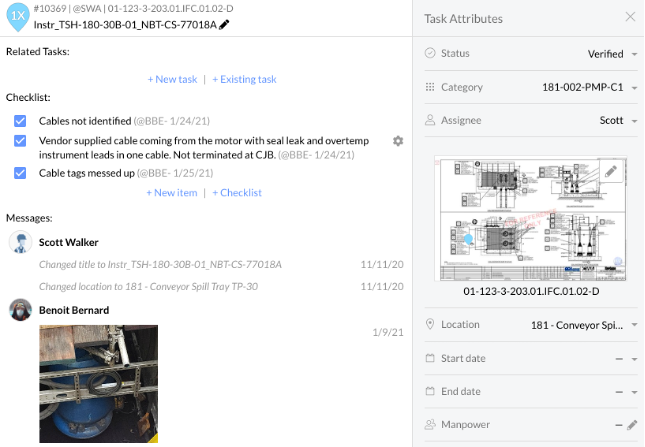

Houle’s work included nearly $80 million in electrical cable, instrumentation, lighting, high-voltage distribution systems, control panels and other electrical installations. One of many subcontractors to Calgary-based general contractor Graham Construction, Houle had to closely monitor its work and that of other subcontractors to stay on schedule. Fieldwire’s capabilities in tracking progress and deficiencies kept things manageable.

“In a perfect world, everything is completed on time,” said Sinclair. In reality, delays experienced by one subcontractor often affect another, and Houle had to explain to the client when electrical work was being delayed by another specialty contractor.

“The client wanted to know where we stood on a daily basis,” said Sinclair.

In addition to working with Graham, Houle worked closely the multinational engineering and construction firm Fluor, which used a proprietary system for managing inspection and testing reports. Houle relied on Fieldwire for cataloging the reports and associating them with tasks and drawings.

New-found Efficiencies

With work tasks linked to drawings, photos, and other documentation such as reports and RFIs, Houle staff could access information much faster than in previous projects, where information was often managed primarily with spreadsheets. With the previous approach, finding a drawing might take 10 to 15 minutes, whereas Fieldwire shortened the process to just a fraction of that time, noted Sinclair.

Printing costs were also drastically reduced, as field staff accessed drawings via tablets instead of paper documents.

Document control was also streamlined. Using Fieldwire’s versioning features, Houle staff could overlay different versions of drawings, quickly identifying updates in new drawings. Because the changes were typically not highlighted or clouded in each new version, the team might have otherwise spent numerous hours manually reviewing drawings to identify changes.

Photo management was eased by linking photos with drawings. Houle was able to drop pins on a specific drawing location and attach a photo to that location, including notes where applicable. In the past, workers had to manually write notes in a PDF editor and store them separately from the drawings, a “labor-intensive” task, noted Sinclair.

Looking Ahead

Houle started using Fieldwire in 2016 and has implemented it on 14 other projects, including a liquified natural gas (LNG) facility, casino, and several healthcare facilities. Sinclair anticipates that number to grow in the near future. He sees additional opportunities for streamlining QA/QC efforts, safety reports and requests for information (RFIs). As the lessons learned from the Neptune Terminals are shared across the company, he anticipates Fieldwire to play a bigger role on future projects.