Capture to construction: Connecting the digital thread in VDC workflows

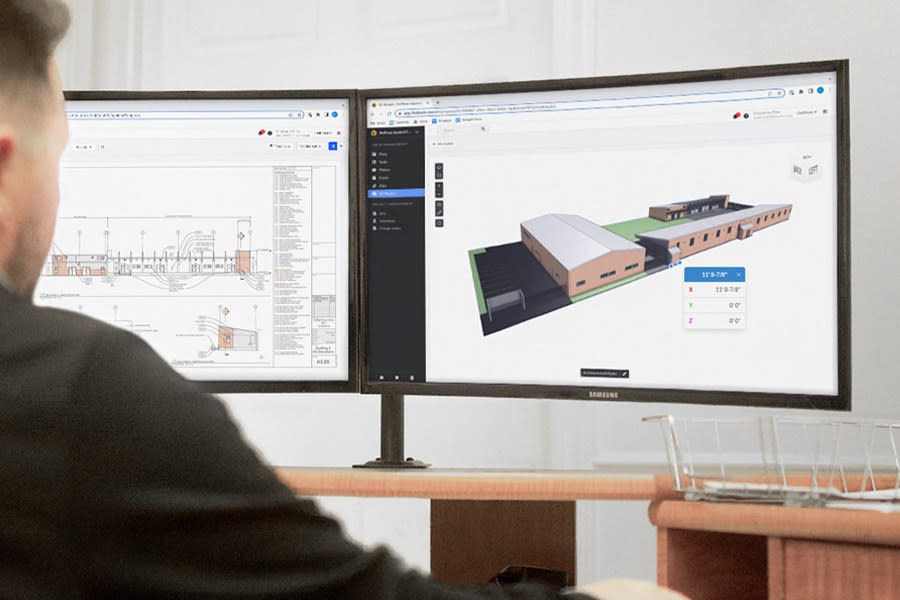

In today’s construction environment, the push toward digital transformation is everywhere—from BIM-enabled designs to cloud-based coordination tools. Yet despite all the technological advances, a critical disconnect still exists between what gets planned in the office and what gets built in the field. Models stay on laptops. Field teams rely on outdated drawings. Decisions lag behind the pace of the job.

I’ve found that bridging this gap requires more than tools—it demands a mindset shift. One that connects technology, workflows, and people across the entire lifecycle of a project. That’s where Capture-to-Construction workflow comes in: a practical, repeatable approach to aligning reality with design from day one.

I’ve broken it down into three core pillars:

- Reality Capture: The digital foundation

- VDC/BIM: The integration engine

- Field Visualization: Bringing it to life on-site

Together, they form a continuous loop that eliminates guesswork, shortens feedback cycles, and empowers teams at every level—from designers to superintendents.

Summary

The Capture-to-Construction workflow connects office and field teams by linking reality capture, BIM integration, and on-site visualization into a continuous loop. By grounding projects in accurate site data, enabling clash detection, and putting models directly in the hands of crews, this approach reduces rework, accelerates decisions, and aligns stakeholders for more efficient, higher-quality project delivery.

Takeaways:

- Reality capture with tools like laser scanning, drones, and 360° imagery ensures projects start from accurate conditions.

- BIM integration turns real-world data into actionable models for clash detection, coordination, and budget alignment.

- Field visualization via AR and mobile apps empowers crews to build with clarity and precision.

- A continuous capture–model–build–verify loop minimizes errors and keeps office and field teams aligned.

- Adopt connected Capture-to-Construction workflows to reduce risk, save time, and deliver projects with greater accuracy.

Grounding projects in reality

Every successful project begins with a clear understanding of the site. Instead of relying solely on traditional site surveys or 2D plans, we now start with reality capture. Using 3D laser scanning, drone photogrammetry, and 360° imagery, we digitize real-world conditions into precise, navigable models.

I recently laser scanned an existing facility and brought the point cloud into Navisworks to compare it with the Revit models we were provided. It didn’t take long to spot the issues—several walls were clearly out of alignment with the design model. By catching these discrepancies early, we gave the design team a chance to adjust before any documentation went out. That one scan likely saved weeks of rework in the field.

In another project, I scanned an existing space for a client ahead of construction kickoff. We brought in the design models right away to visualize where problems might arise if things weren’t addressed. I’m now working directly with the VDC lead to create a combined “clash” view that clearly shows the client how their design stacks up against real-world conditions. The goal is simple: help them make informed decisions before a single trade mobilizes.

From raw data to smart decisions

Once the physical world is captured, our VDC team turns that data into something actionable. Through Building Information Modeling (BIM), we create digital environments that layer in design intent, coordination strategies, and constructability reviews.

This stage isn’t about modeling for modeling’s sake—it’s about making better decisions before they impact the field. By integrating real-world data into BIM workflows, we enable clash detection, phasing simulations, and budget alignment—all before any work begins.

The result? Fewer surprises. Fewer RFIs. And a model that evolves with the project.

This approach gives contractors foresight and flexibility. Engineers collaborate more easily across disciplines. And owners gain confidence that what’s being designed can be built with minimal waste and delay.

Putting the model in the hands of the field

The most powerful model in the world is useless if it lives in an office silo. That’s why field visualization is the third and most critical part of our workflow. We use mobile apps, augmented reality, and interactive BIM viewers to make sure crews on the ground can interact with models in real-time.

Whether it’s overlaying mechanical layouts using a tablet or validating concrete embeds with AR, our field teams gain a new level of clarity. No more flipping through 50-page drawing sets. No more waiting for clarification from the design team.

This real-time access empowers field personnel to catch issues early, build with precision, and stay engaged in the process. It brings office and field into alignment—just where we need them to be.

Closing the loop

The biggest shift in this workflow isn’t technological—it’s behavioral. Because after the model is used in the field, we capture again. We scan to verify, validate, and close out. This feedback loop—from reality capture to modeling to field execution and back again—is what keeps quality high and errors low.

It’s not just a one-time process. It’s a mindset of continuous refinement and connection. One that’s helping our teams deliver projects more accurately, efficiently, and confidently.

The opportunity ahead

The construction industry doesn’t need more tools—it needs more connected workflows. By grounding our projects in reality, modeling with purpose, and visualizing where it matters most, we’ve found a way to bring BIM out of the office and into the field, where it belongs.

For teams looking to tighten the digital thread between design and delivery, this isn’t some future-state vision. It’s happening now—and it’s delivering results.