8 essential steps for effective project cost estimation and budgeting

To say that winning bids is the key to success in construction is a half-truth. Estimating project costs correctly and managing the budget accordingly are just as vital.

Subcontractors getting awarded a contract spells financial disaster if the bid is too high to be competitive or too low to be profitable. Submitting a price within the Goldilocks zone can be challenging. You must have domain expertise and foresight to calculate how much everything will cost, avoid charging too little and spend funds properly.

All subcontractors make project cost estimation and budgeting errors. You can learn from your mistakes and get wiser with experience and insight. However, only some businesses can afford to commit too many faults to keep the lights on. Follow these eight essential steps to estimate project costs and budget funds effectively to prevent grave miscalculations.

1. Study the project details

Understand the construction project’s specifications and requirements during the bid solicitation phase. Paying close attention to these details can help you determine whether you’re qualified for the job and should submit a proposal.

Bidding on projects you have yet to gain experience in can broaden your horizons. However, trying to be a specialty contractor for everyone can backfire. Concentrating on jobs that fit with your business has merits.

Establishing a solid reputation for specific projects can increase your hit ratio. Property owners can find your credentials impressive and confidence-inspiring when you’ve been around the same block a few times. Finding your niche can benefit your brand, gaining repeat business from general contractors and design-build construction firms.

For example, focusing on green projects in your county where recycled and carbon-neutral materials are paramount can make you the local authority in sustainability. Zeroing in on historic restoration jobs is another way to differentiate yourself from the competition.

In contrast, trying your luck on any project coming your way can lower your chances of winning a contract. Construction project stakeholders expect you to self-regulate and reflect on whether you’re up to the task. Even experienced subcontractors can seem like novices when bidding on jobs outside their areas of expertise.

You may underestimate the job’s scale and complexity if you outbid others when you're unqualified. Biting off more than you can chew can put you in a bad light.

2. Perform a material takeoff

Conducting a material takeoff is a sound practice to identify and address discrepancies early. General contractors can review all available construction documents or the bill of quantities the property owner or project engineer prepared. Subcontractors can do a separate takeoff based on the general contractor's specs to verify material and equipment quantities and ensure an accurate count before contacting suppliers and vendors.

3. Solicit pricing information

Request quotes from various sources and study their pricing structures. Consider how much savings you can get when ordering large quantities. Buying slightly more than needed may entitle you to bulk pricing discounts.

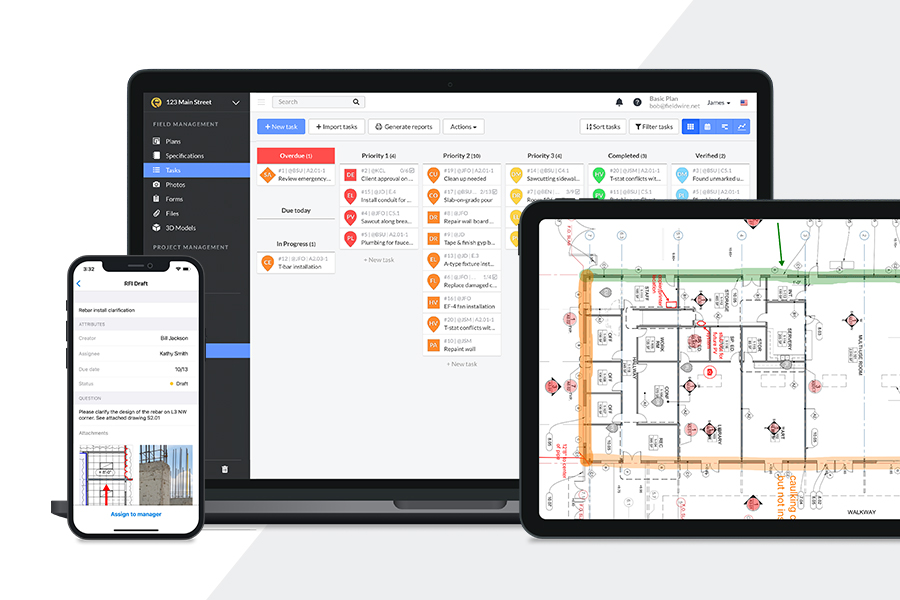

Factoring material waste into the equation can reveal how many additional supplies you should procure to prevent delay. This task may involve guesstimation, although your life will be easier if you track this information through construction software. Digital data lends itself to analytics. It enables you to evaluate your past projects and have a concrete basis for the amount of extra materials you should order.

Quality must take priority over price. Although almost any product has a budget-friendly option, finer materials contribute to functionality, aesthetics, safety and longevity. Skimping on supplies can save you money once. However, investing in quality items can keep you in business for a long time. It can help you build a reputation for excellence and ensure counterparty satisfaction consistently.

Ask about quote expiration, too. Suppliers and vendors rarely wait forever. Determine whether their offers are valid until you snag the contract to see if you can count on them.

Regarding tools and machines, renting what you seldom use for projects is smart. It spares you from maintenance and storage duties.

4. Calculate labor costs

Labor costs include worker wages, taxes, insurance premiums, retirement contributions, vacation and sick leaves, and union dues. These expenses multiply for every extra person you have on staff.

Know the exact roles the project requires and the hours needed to complete the job to build the right crew.

If you don’t have enough employees, use independent contractors to round out the team. They can reduce your labor-related expenses since they’re not entitled to the federal minimum wage and overtime pay.

Sadly, many construction businesses purposely misclassify their employees as independent contractors to slash their payroll costs by up to 50% and shrink bids by 25%. The financial advantages may be enticing, but decide against it to avoid getting sued.

5. Determine indirect expenses

You must estimate insurance, bonds, indirect field expenses and overhead costs. Insurance and bonds particularly matter because they mitigate risks for all stakeholders and make you a safer party to do business with.

Integrating overhead expenses into estimates accurately is simple. Discerning estimators determine the business’s expected annual revenue and overhead cost when assigning a specific percentage of the overhead to a project.

6. Prepare for contingencies

Unknown and unforeseen events can lead to budget overruns, so setting aside a contingency fund is necessary. Gleaning insights from past projects can help you determine a reasonable amount to add to your estimate and keep from pulling a number out of thin air.

Sometimes, property owners have contingency limits. For example, the Washington State Department of Transportation bars contractors from allocating more than 4% of the contract amount for contingencies.

7. Take target profit into account

Determine a suitable profit margin to make the project worth your while without turning off property owners. On average, remodelers net 4.7% before taxes. Regardless of how you feel about this figure, it’s an excellent reference point for deciding how much you should charge.

The construction bidding process is only a meritocracy occasionally. Charging too much is a losing strategy if you bid on public projects because government rules generally favor the lowest bidders.

On the contrary, commercial property owners are more keen on hiring contractors with stellar project experience, scheduling philosophies and safety records, even if it means paying more.

8. Technologize budget management

Responsibly spending funds is a different skill. Ensuring the project costs as close to the estimate as possible is the ultimate goal. Preventing unnecessary expenses within your control is a must.

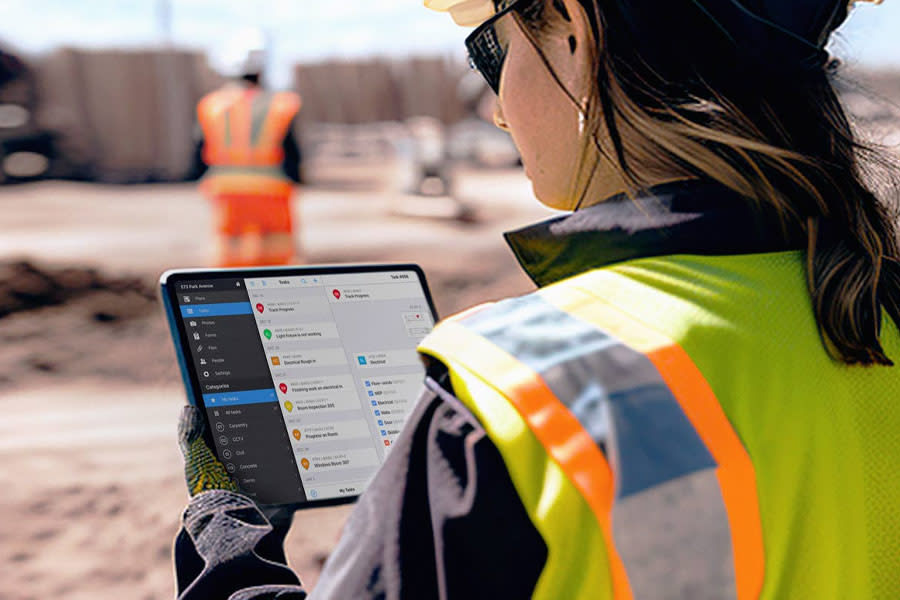

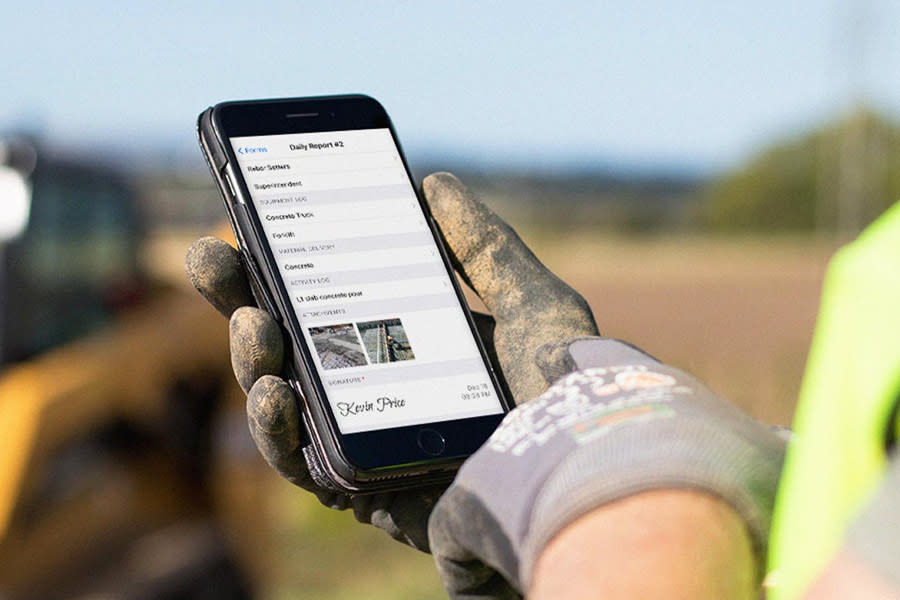

Tracking how much money goes out of your account manually isn’t the most efficient method. Instead, use a construction management program to stay on top of your budget. Cloud-based tools designed to keep tabs on invoices and compare actual spending against the budget are indispensable. They can help you economize in every area, finish the job on schedule and get paid ASAP.

Underestimating estimation and budgeting errors is costly

Estimates are no guarantees of cost overrun avoidance. What’s certain is getting them wrong can put you out of business sooner or later. Let the above steps guide you and trust the process.

Rose Morrison •

Rose Morrison •