5 Technology Innovations that May Soon Impact Your Business

With decades of proven methods and techniques, the construction industry is not always quick to adopt new technologies. Many firms are reluctant to hop on new bandwagons when they already have established processes that seem to be working just fine. Here are five innovations that might cause you to reconsider that approach, as these technologies are increasingly finding practical applications in the field. Some are relatively new, while others have been available for several years, but have recently made significant strides in providing value.

1. Construction Robotics

While robots are not likely to replace humans for most tasks, they are making inroads in assisting humans with key tasks. Spot, a four-legged robot from Boston Dynamics has been used to gather site data and monitor field conditions on several large projects for Alabama-based contractor Brasfield & Gorrie and a mixed-use redevelopment in South London for Foster + Partners. By automating repetitive tasks and eliminating the need to send workers into hazardous conditions, the robot can increase efficiency and improve workers’ health and safety.

ULC Technologies developed the Robotic Roadworks and Excavation System (RRES) to help utility companies, energy networks, and other industries streamline infrastructure work. The all-electric system has been used on several projects in the U.K. and the U.S., combining location sensors, artificial intelligence, and machine learning to automate inspection and repair of pipelines and other underground facilities.

FieldPrinter from Dusty Robotics automates layout work, replacing tape measures and chalk lines with full-size markings of digital building models in the field. In addition to accurately marking layout lines and component locations, the system can provide additional information from plans and shop drawings, such as part numbers and dimensions.

Other robotic systems are in various stages of deployment to automate manufacturing of construction components, transport equipment and tools, and perform repetitive tasks, such as tying rebar and placing bricks. Time will tell how far these systems reach into construction operations.

2. Digital Twins and BIM

The concept of a digital twin -- a dynamic, up-to-date digital replica of a physical object -- has been around for decades, but has recently been garnering increased attention in construction. Expanding on the building information modeling (BIM) concept, where CAD models contain intelligent information along with traditional lines and shapes, digital twins can be updated in real time to monitor a project’s status throughout all phases and simulate, predict, and guide decisions. CAD software heavyweights Autodesk and Bentley are heavily involved in this, as well as numerous smaller developers.

For example, STRATUS software from GTP enables custom work packages and spools to be created directly from a CAD model. Construction teams in the mechanical, electrical, and plumbing (MEP) sector can create cut lists and send them to fabrication shops for spooling.

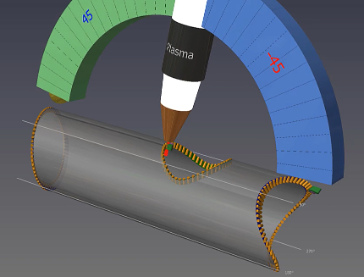

PypeServer from the company of the same name, connects CAD and BIM tools to a cutting machine to tightly control pipe cuts. This helps contractors reduce waste and automate pipe fabrication.

3. Wearable Devices

Wearable devices such as hard hats, gloves, safety vests and work boots are increasingly being outfitted with sensors, location trackers, and Wi-Fi to monitor workers’ movements and locations. By doing so, repetitive motions, slips, falls and other hazardous situations can be detected -- and in some cases avoided. Wearables with biometric sensors can track heart rate, body temperature, and other vital signs and send notices if a worker is potentially suffering from exhaustion or becoming overheated.

Solepower’s SmartBoot provides real-time location and data tracking of workers via footwear-embedded sensors. Data from GPS, RFID and inertial measurement sensors are sent to the cloud and projected on a dashboard. In addition to providing accountability and emergency response features, the device can preemptively identify fatigued employees by the change in their gait along with other parameters. Productivity measurements can be developed by task as fatigue increases, calibrating the point of diminishing return.

WakeCap captures data from smart hardhats and a scalable site-mesh-network to provide project management reports and improve worker safety. Data can be used to analyze site workflow, congestion, workplace safety, and employee tracing for health risks, such as Covid-19.

Another headgear-related product focuses on simply improving illumination. The Halo SL from ILLUMAGEAR, Inc. clips onto a hard hat to provide a personal lighting system 360-degree visibility for 1/4 mile, flood task lighting and a 50-foot spotlight.

4. Safety Sensors/IoT technology:

Closely related to wearable devices is a broad category of devices and software – loosely called the Internet of Things (IoT). These devices essentially apply the concept of “talking to each other” to share data and improve efficiency and safety.

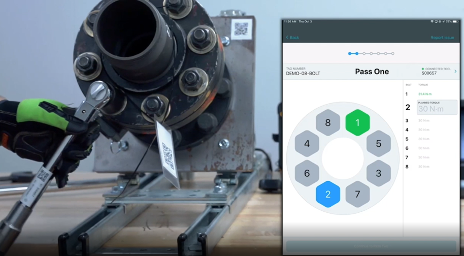

Cumulus’ Internet of Tools is a platform that collects data from digitally-enabled tools in the field to provide real-time quality assurance and progress tracking. The platform replaces manual inspections with software and tools that automate data recording and reporting. The company’s flagship product, the Smart Torque System, collects data generated during industrial bolting activities to provide real-time feedback and track quality.

Spot-r Radius by triax is a system that provides safety alerts, monitors equipment usage, and creates daily analytics reports. With gateways placed strategically around a site, tags are attached to workers or equipment to monitor usage and proximity to hazardous areas. Beacons transmit data to the cloud at the end of each day for report creation.

The Smart Safety app from CKM Technologies, LLC uses GPS-based geofencing technology to issue emergency alerts within the boundaries of a jobsite. Administrators establish geographical boundaries, and set up alerts that are activated when individuals carrying smart phones and/or tablets enter or exit a particular area. In the event of an emergency, a user inside the boundaries of the geofence can issue an alert that sends an emergency notification, specific to the crisis, to all other app users who are inside the geofence’s parameters.

5. 3D Printing

Once considered limited to prototyping and manufacturing small products, 3D printing has progressed from a novelty to a key player in construction. Also known as additive manufacturing, 3D printing builds a three-dimensional object from a digital model by injecting or extruding material onto a platform according to the model. In construction, the material may be concrete, polymers, or other materials -- in lieu of ink used for printing on paper. A bevy of firms have thrown hats into the 3D printing ring.

![]()

ICON Technology, Inc. uses its Vulcan 3D printing system to print homes and other structures up to 3,000 square feet. The company’s proprietary Lavacrete reaches a compressive strength of 6,000 psi, similar to that of high-strength concrete.

PERI 3D Construction uses a BOD2 printer manufactured by COBOD to build a variety of structures. The printer consists of a gantry system with multiple modules that can be expanded, moved, and set up in various configurations. PERI offers the printer for sale or rent, and also performs 3D printing as a service.

Branch Technology is a prefabrication company that uses a cellular fabrication process combining industrial robotics and a freeform extrusion technology. This process allows the material to solidify in free space without dimensional restrictions or support structures. It has been used on numerous projects such as facades for parking garages, libraries, and art museums.

What Next?

Numerous other technologies are also making headway in construction. Intelligent construction vehicles, advanced surveying technology, artificial intelligence and virtual reality are just a few that are becoming more commonplace. In some cases, multiple technologies are being combined to explore new possibilities. While the extent of impacts in construction is yet to be determined. contractors would be wise to stay tuned and prepare for the future.

To understand how Fieldwire can help you and your team manage people and projects more efficiently, please register for a live demo of our platform below.

Andrew Roe •

Andrew Roe •