5 steps construction managers can take to help implement new tech to their crew

The construction industry has historically been slow to adopt technological changes, but that attitude is starting to change. Tech integration is becoming much quicker and more efficient as the next generation of employees joins the workforce and new subcontractors take up leadership roles.

Benefits of implementing new technology

Implementing new technology has many benefits. The common misconception is that only big companies with flexible budgets can afford it, but that’s not true. Small to midsize contracting businesses and independent subcontractors can get a full return on investment and reap these benefits:

-

Efficiency: Using the latest technology allows contractors to manage their projects more efficiently, from day-to-day jobs to business administration. Controlling expenses and sharing valuable information with employees also becomes much easier.

-

Visibility: The growth of monitoring tools such as construction wearables and drones provide full visibility of the worksite, resulting in fewer incidents and projects of higher quality.

-

Sustainability: As consumer attitudes about the environment change for the better, transitioning to more eco-friendly technologies will help your business resonate with the next generation of homeowners.

-

Engagement: New technology improves engagement among employees and customers. Employees have more tools at their disposal and customers feel greater assurance with a well-equipped construction crew building their homes.

-

Long-term growth: Tech integration enables your company to sustain long-term growth without consuming too many resources or creating conflicting interests between departments.

New technology can also make construction safer than ever before. About 59.9% of construction fatalities happen because of four main causes — electrocution, falling from great heights, being struck by objects and getting caught between things. Greater efficiency and visibility mean your crew will experience fewer accident-related setbacks.

Here are five steps construction managers should take to successfully implement new technology.

1. Prioritize the right technologies

Most subcontractors don’t have the funds to invest in new technologies, but that shouldn’t hold you back. Prioritizing just a handful of things is better than making numerous investments at once. Integrating tech in small doses will make the learning curve more manageable for your employees.

The eye-opening 2021 KPMG Global Construction Survey found that construction and engineering professionals think highly of some technologies but not others. According to this survey, the following tech has the most return-on-investment potential for construction companies:

- Integrated project management information systems

- Building information modeling (BIM)

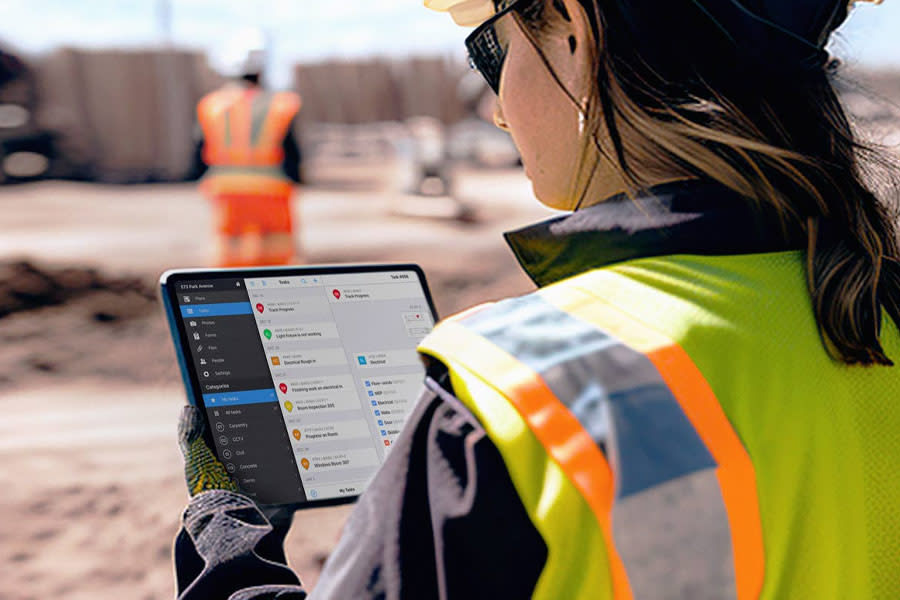

- Mobile communication platforms

- Advanced data analytics

- Smart sensors

- Construction drones

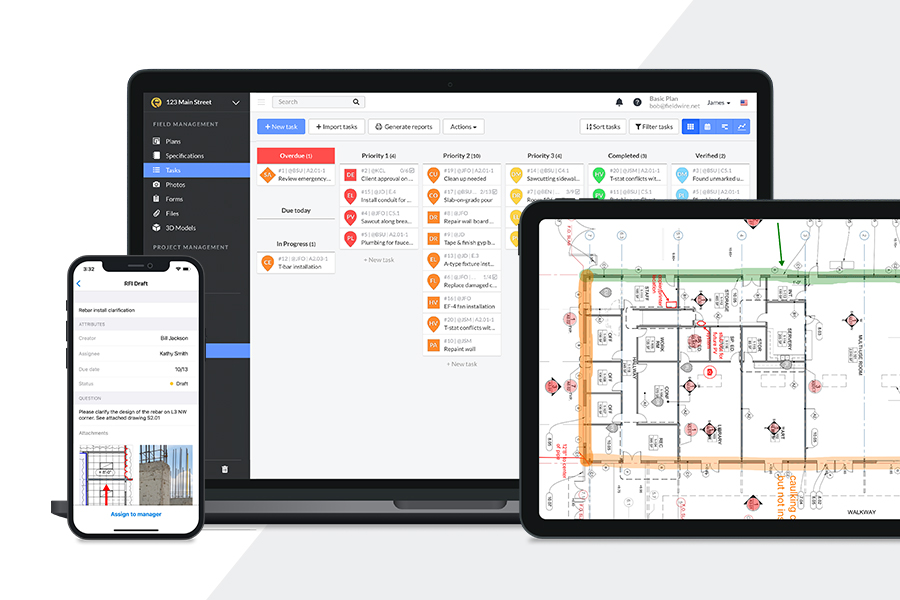

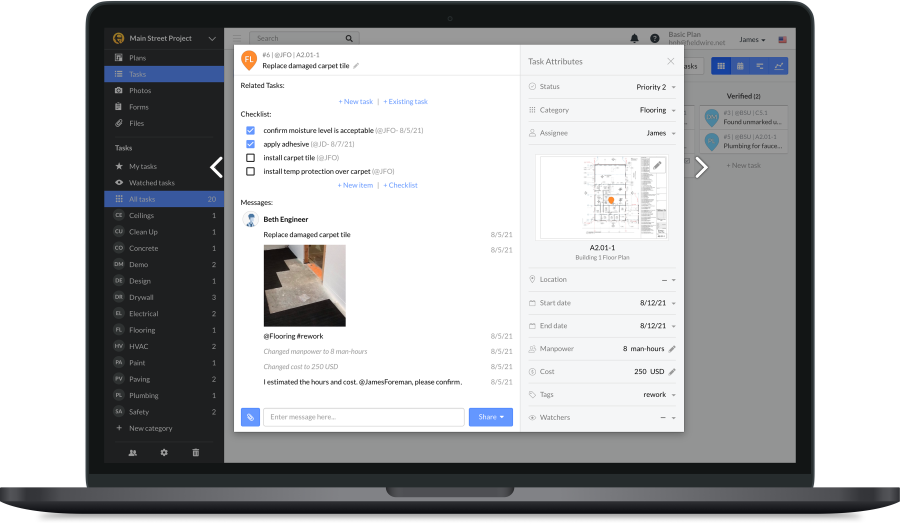

Before diving into 3D printing, virtual reality and other technologies still in early development, focus on the tools with a proven track record of success - like Fieldwire's all-in-one jobsite management software. You will have an easier time getting buy-in from your employees and training them in a timely manner.

2. Foster an ongoing learning environment

You should foster a supportive ongoing learning environment. This can be challenging for managers in an industry with high employee turnover rates because you rarely hold onto the same workers for long. However, every company’s culture is different. Yours can be the exception to the rule.

The main idea of ongoing learning is to institute an in-house training program with no definitive ending. It focuses on incremental improvements to various skills rather than one lesson for a long duration. This can include learning about new technologies, among many other things:

- Soft skill development

- Specialized equipment operation

- Safety protocols

- Emergency preparedness

- Time management and deadlines

Ongoing learning includes a balance of mentorship and individual assignments, which makes it highly flexible to different learning styles. Mentorship is a crucial part of labor-intensive industries like construction because it promotes a hands-on approach to learning and enables employees to pick up new skills and technologies quickly.

3. Take advantage of educational materials

Construction companies have a wealth of educational materials at their disposal to assist with tech implementation. Organizations like the Associated General Contractors of America and the National Association of Home Builders provide numerous courses about management and the latest building technology.

You should also consider taking team members to construction seminars or team-building conferences. Attending these events can help your crew gain valuable insights and buy into emerging technologies and practices. Fieldwire holds monthly live webinars to educate new and existing customers about best practices and innovative ways to use the construction management software, giving the opportunity to your teams to get quick answers to their questions about the app.

Attending events is also an excellent opportunity for construction managers to network with other business leaders. You can discuss the strengths and weaknesses of your learning programs and the successes and challenges of different technologies.

4. Sign up for the latest certification programs

New certifications will emerge as the construction industry adopts new technologies globally. Your company must stay on top of them and sign up for the latest programs. Skill development is a bigger priority than ever, with 95% of American contractors considering their crews to have underqualified skill levels.

There are thousands of certifications to choose from, but programs from organizations will be the most effective at helping your team adopt new technologies:

- Project Management Institute (PMI)

- Certified Professional Contractors (CPC)

- National Center for Construction Education & Research (NCCER)

- National Institute for Certification in Engineering Technologies (NICET)

You should also encourage employees to obtain the latest certifications in different subcontracting fields, including plumbing, roofing, masonry and electrical work. They will be able to focus on new technologies that pertain to their specific areas and make progress more quickly.

5. Keep a tech integration calendar

Keeping a calendar is a great way to maximize creative output and get your employees to embrace new technologies. You can assign projects and lessons months in advance, giving workers time to mentally prepare for the upcoming challenge. Calendars are simple methods of making drastic changes more palatable, which is crucial when introducing new technologies.

Starting a calendar also enables you to give each employee enough attention. You can host individual touch points on prescheduled dates to monitor their progress and obtain feedback. Scheduling team meetings will help the whole crew exchange ideas and opinions about the latest tools they’re using.

Implement new tech one day at a time

All five tech implementation strategies follow the same principle — take things one day at a time. You can’t put too much pressure on your employees to learn new technologies on the fly. They need an ongoing learning environment, plenty of educational resources and an organized schedule to absorb all the knowledge and skills required to succeed.

Rose Morrison •

Rose Morrison •