With inflation, how can we help construction costs stay down?

Inflation has been hard on the construction industry. The sharp rise in prices has made essential materials such as steel, lumber and insulation unaffordable for many professionals, especially independent contractors. How can you keep your construction costs down to minimize the impact of inflation?

Inflation has been hard on the construction industry. The sharp rise in prices has made essential materials such as steel, lumber and insulation unaffordable for many professionals, especially independent contractors. How can you keep your construction costs down to minimize the impact of inflation?

Invest in Big Data

“Big data” is an umbrella term for technology that gathers large amounts of data to help business leaders make more informed decisions. You might not have much financial wiggle room to make a significant investment, but there are many technologies to choose from. All in all, the return on investment makes up for this and contractors should find a way to integrate these big data technologies into their operations.

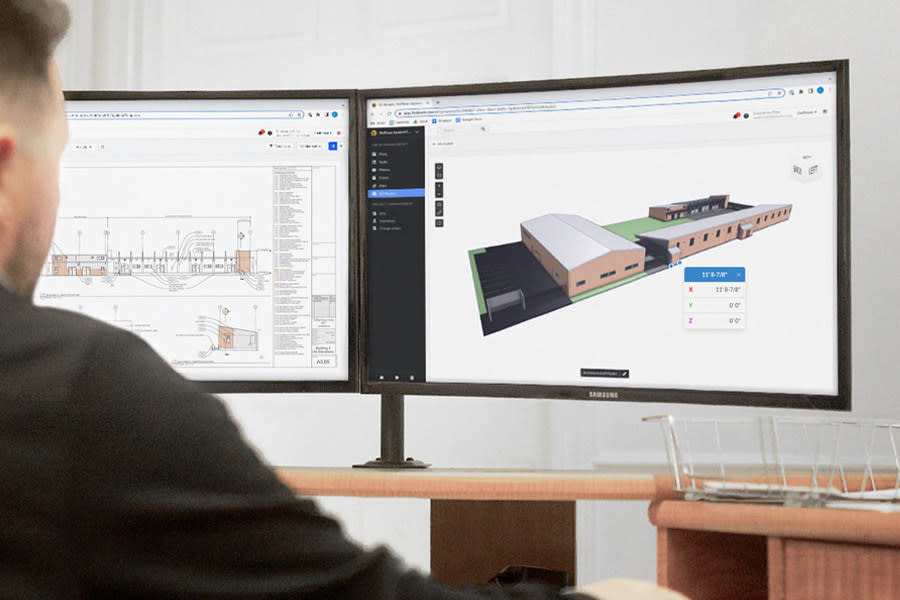

Building Information Modeling

Building information modeling (BIM) can be your saving grace. BIM provides real-time data on material costs and availability, helping you stay up-to-date on deliveries despite high prices and material shortages. You can clearly see the project’s expenses through the design, building and clean-up stages.

While the cost of rework hovers around 2.4%–12.4%, studies have found it can go as high as twenty percent. BIM can help you reduce that number to zero for all your projects. It enables you to mitigate security threats, safety hazards, equipment damage and even human error. The technology’s three-dimensional building models are full of valuable information about the structure’s geometry, allowing you to identify the smallest mistakes.

BIM can even be a personal safety monitor for independent subcontractors. With no one to supervise the site, BIM’s clash detection feature can help you identify injury risks before disaster strikes, saving you from project delays and costly medical bills.

The software is also useful for cutting costs during your project’s closing stages. You can review your closing checklists and review the project’s entire update history, including any setbacks. These final insights can help you identify overarching inefficiencies that might have increased the project’s total cost.

IoT Tracking Solutions

The Internet of Things (IoT) is a network of sensors and software that collect and exchange data with each other. IoT tracking solutions help contractors maximize visibility with their suppliers and identify potential delays. You can track the location of all material deliveries in real time and plan your projects accordingly.

IoT applications can also help you track new expenses on the construction site. You can use connected sensors and actuators to monitor every aspect of the built environment, including the conditions of your tools and equipment. They will help you make your operations more efficient and eliminate avoidable overrun costs.

Wearable sensors have been perhaps the most popular IoT technologies in construction so far. You can wear internet-connected sensors on your helmet, vest, gloves and other clothing articles to collect information about your work habits and physical health. They will help you stay on task and maximize productivity.

AI and Blockchain Technology

Contractors might not be able to control inflation, but they can control their spending. Artificial intelligence and blockchain technology have greatly influenced the construction industry in reducing expenditures. Management software with AI can automatically monitor all of your transactions and identify irregular spending trends, which helps you avoid unnecessary expenses in the future.

Blockchain technology plays a specific role in synchronizing data across different networks. It creates full trust and transparency in online transactions, helping you safely execute contract negotiations and removing the need for expensive intermediary third parties. You can do business peer-to-peer with minimal paperwork and maximum efficiency.

Stockpile Alternative Materials

You can’t rely on just one supplier or material during these unstable times. You need to connect with multiple vendors and stockpile alternative materials in case your first choices don’t work out. Look for suppliers with their own diverse vendor bases, convenient locations and reliable lines of communication.

The stockpiling strategy allows you to expand your use of sustainable materials and branch out to more eco-friendly suppliers. You might not use them immediately, but you can slowly build an inventory of reclaimed wood, recycled plastic, precast concrete and other green building materials.

The stockpiling strategy has become much more common since COVID-19 halted global supply chains. Builders, manufacturers and retailers are acquiring lots of warehouse space to build up their raw material supplies.

Building up an inventory is slow and steady work for small-scale contractors, but you have a long-term advantage over your bigger competitors. The best time to stockpile materials is when you’re going through rapid growth. Since you need to buy many materials anyway, you can simultaneously add to your inventory.

You should also stock up on materials when you anticipate delivery disruptions or have a busy schedule coming up. You won’t have time to focus on material shortages during these chaotic periods, so you need to increase your inventory now while things are still calm.

Do More Vulnerability Assessments

Due to the construction industry’s ongoing essential material shortages, a project delay is bound to happen eventually. Construction contractors need to know their strengths and weaknesses to contain the effects of a disruption. You should increase the frequency of your vulnerability assessments for this reason.

If you currently do vulnerability assessments every quarter, change it to a month or every two weeks. You should also assess if any of the following changes affect your business:

- You switch to another supplier

- One of your suppliers changes its location

- One of your suppliers changes the cost or availability of its materials

- A new security or safety risk emerges

- You introduce a new technology to your operations

Every time your business or one of your suppliers experiences a notable change, you should perform a vulnerability assessment. This precautionary measure will go a long way toward helping you avoid future pitfalls and unnecessary expenses.

Minimize Your Construction Costs

The construction industry could afford to be wasteful when the economy was strong and supply chains were moving as scheduled. With the current economic conditions, there are better options than wasteful spending. Contractors must adopt new technologies, stockpile materials and perform routine vulnerability assessments to minimize construction costs and compensate for inflation.

Rose Morrison •

Rose Morrison •